Unlocking potential: how Augmented Reality reshapes assembly workflows

The challenges of traditional industrial assembly processes include reliance on complex manuals, varying skill levels among technicians, logistical difficulties of remote assistance, and the intensive resource requirements for training and onboarding. Augmented Reality provides a transformative solution for increasing precision, efficiency, and training in assembly processes.

Evolution of assembly workflows with Augmented Reality

Traditional assembly workflows often rely heavily on paper manuals, extensive training sessions, and the physical presence of skilled technicians. This approach comes with limitations such as increased time consumption, higher costs, and limited flexibility.

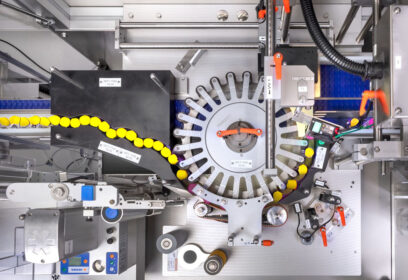

Augmented reality assembly introduces a paradigm shift by overlaying digital work instructions, 3D models, and real-time support directly onto the physical workspace through smart glasses or mobile devices. This innovative approach allows for:

- Enhanced Precision: Digital overlays guide technicians through complex assembly tasks, reducing errors

- Streamlined Training: New employees can be trained more effectively with interactive AR-driven assembly instructions

- Increased Efficiency: Real-time remote support and digital guidance reduce the need for on-site expert visits, significantly cutting down travel costs and downtime

- Improved Flexibility: No need to overhaul traditional documentation and training materials in order to changes in product designs or processes

- Unlock the potential of your assembly workflows with Digital Work Instructions

- Find out how to optimize operational efficiency

The impact of AR Remote Support on the processes

Acty’s remote support is designed to directly address operational and process challenges, leveraging AR to streamline and enhance assembly workflows. Through AR smart glasses, technicians can receive real-time support from experts, regardless of geographical distances*, developing also a standardization of processes: a standardized approach to training and assembly processes can be enabled, ensuring consistency and quality across the board.

*Acty has a built-in voice translator with more than 100 languages available.

Several customers are already benefit from such an approach. Among other Swift-Cut, global leader for the design and build of high quality, affordable CNC plasma and waterjet cutting machines, has implemented Acty in its processes in order to improve the value of remote industrial assembly and installations.

- Discover the main use cases of Augmented Reality in the Laser Cutting field

- How to provide intuitive, efficient, and easy-to-use AR Remote Support

Addressing assembly challenges with Acty

Using a structured Augmented Reality environment in assembly and installation processes must become the approach followed by B2B companies in order to foster a deeper connection with their customers, by providing a level of support and engagement that traditional methods cannot match.

Acty’s benefetis underscore AR’s potential to not only solve existing challenges but also to unlock new efficiencies and capabilities within the industrial sector, overcoming traditional challenges in operative workflows.