Lean Manufacturing

How are performing your Standardized Work Instructions in Lean Manufacturing? With our Work Instructions you can achieve processes repeatability and eliminate human error in Lean Manufacturing.

Eliminating human-related errors in Standardized Work Instructions

If you work in Lean Manufacturing you should consider the Digital Work Instructions, to optimize production processes and to minimize waste, maximizing processes efficency.

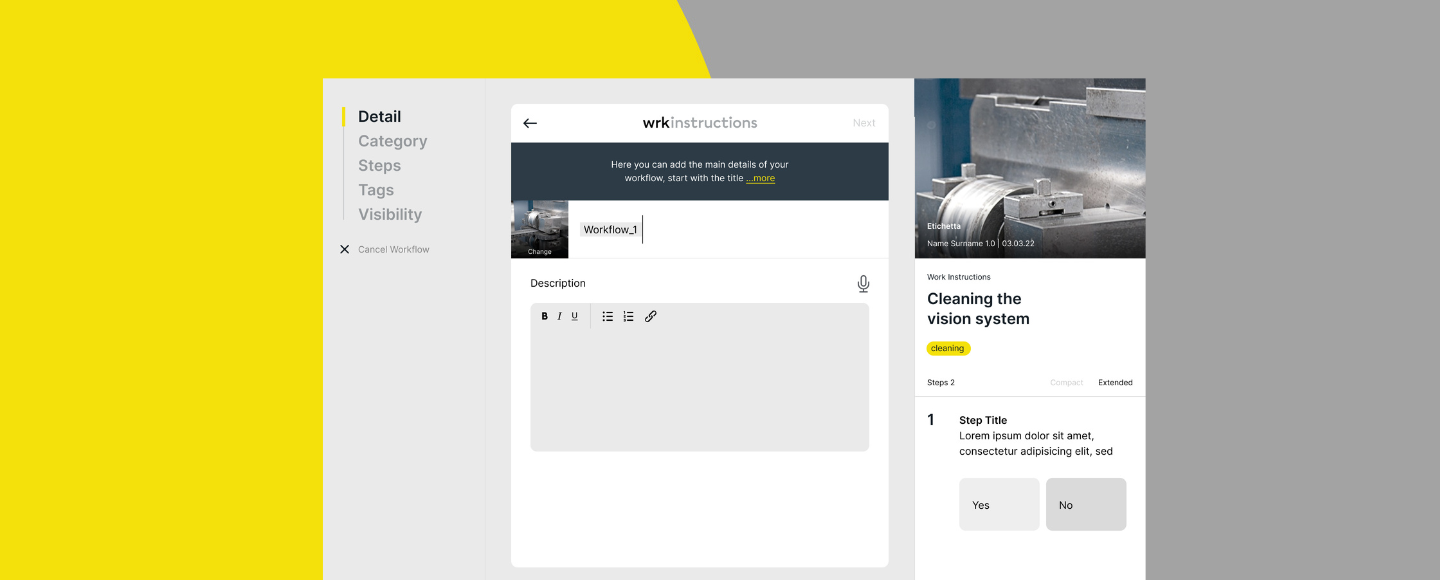

Standardized Work Instructions are a tool to guide operators through each phase of the production process. They ensure repeatability reducing the risk of human errors, providing consistency and efficiency to your Lean Manufacturing production.

These digital instructions can be consulted on smartphones and mobile devices, without install apps nor using manuals.

SWI for Lean Manufacturing consistency

Standardized Work Instructions ensure not only the consistency and repeatability of processes, but a more informed, agile, and productive working environment, too.

Standardized Work instructions tool is very functional for companies adopting Lean Manufactuing production, aiming at optimize production processes. Operators are no longer bound to paper manuals or static boards, but have access to digital instructions directly from their devices, without needing to install dedicated apps.

Discover how to maximize consistency with our Digital Work Instructions

Main use cases of Standardized Work Instructions in Lean Manufacturing:

INSTANT ACCESSIBILITY

Information are immediately and easily available, ensuring quick adoption of procedures.

UP-TO-DATE INSTRUCTIONS

Operators have always access to the most up-to-date instructions.

REPEATABILITY

Each operation is executed identically each time, irrespective of the operator.

ERROR REDUCTION

Operators are guided through clear procedures, reducing the risk of human errors.

WASTE LOWERING

Reduced operating and production costs as error and time reduction.

PERFORMANCE MONITORING

Track and analyze of operators and processes performance

Digitalization of Standard Work Instructions: a step towards efficient manufacturing

Technicians and operators can easily access to all production information provided with digital Standardized Work Instructions. Implementing augmented reality, interactive elements, and instant remote assistance directly into digital instructions, operators are furnished with an enriched, supportive environment that preemptively addresses potential errors

Digitalizing operational instructions company can boost the strategic alignment of workflow processes, ensuring robustness and coherence in production

Smart Glasses for Remote Assistance in 3D

The use of Smart Glasses helps the technicians to improve the cost-effectiveness in Lean Manufacturing, receiving immediate instructions to intervene.

Smart Glasses are complemented in Acty remote assistance software and reduce the risk of human errors during machine maintenance, enhancing workplace safety.

Improve your Lean Manufacturing efficency

Contact us to find out how digital work instructions and remote assistance can be applied to your lean manufacturing production.

Contact usService Hub web portal to support your customers

Service Hub is a portal which semplifies customer support activities for companies adopting Lean Manufacturing structure. It reduce operational costs covering a 24/7 assistance, considering time zone differences, and satisfying requests worldwide.

Moreover, with Service Hub you can generate recurring revenues by monetizing post-sales support.

Some of our clients

Standardized Work Instructions is a software developed by Icona Srl

Let Icona Srl help you communicate with your counterparts at every touchpoint. Our easy-to-use customer support software easily adapts to different company needs and implements innovative technologies that will become your market differentiating factors.

Standardized Work Instructions is a software developed by Icona Srl

Let Icona Srl help you communicate with your counterparts at every touchpoint. Our easy-to-use customer support software easily adapts to different company needs and implements innovative technologies that will become your market differentiating factors.